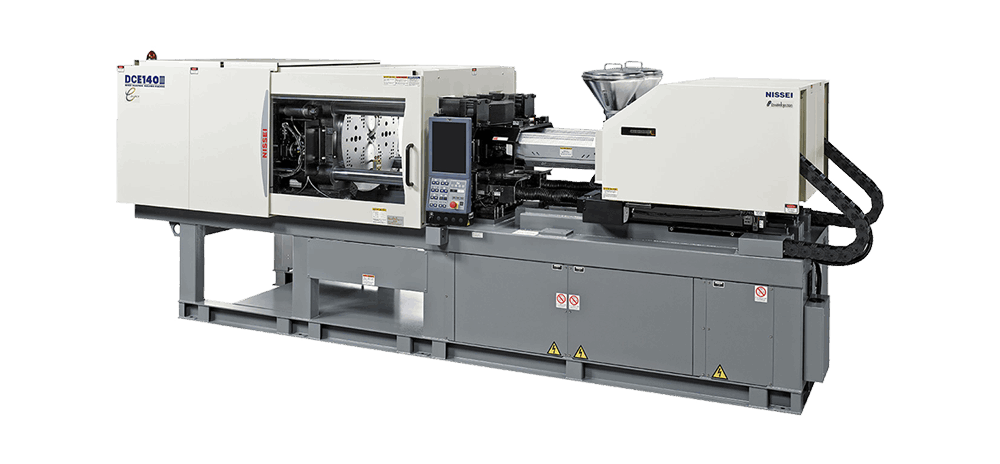

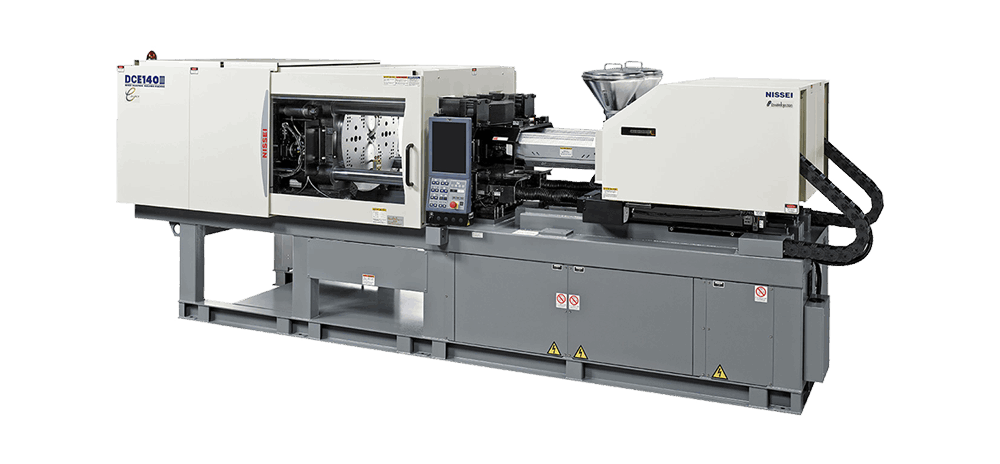

DCE-III Series

ALL-ELECTRIC TYPE 2-COLOR/DISSIMILAR MATERIAL IMM

Clamping force: 140~250 ton (154~276 USton)

- All-Electric

- Horizontal

- Double Flat Clamp

- Double Injection

- TACT® Ⅳ Controller

The DCE-Ⅲ Series, consisting of all-electric type 2-color/dissimilar material injection molding machines, has the mold-friendly high-rigidity "Double Flat Clamp" clamping mechanism, and high-performance/functioning "TACT® Ⅳ" controller. "Double Flat Clamp" mechanism was created by utilizing the NEX Series' "Flat Clamp" (linear-pressure toggle mechanism) and idea of direct-pressure 2-piston type clamping mechanisms. It demonstrates superb performance in high-grade molding and achieves significant energy-saving.

| Item | Unit | 5E (A: 5E & B: 5E)* | | | 9E (A: 9E & B: 9E) | | | 12E (A: 12E & B: 12E) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Screw diameter | inch (mm) | 0.87 (22) | 1.02 (26) | 1.10 (28) | | | 1.02 (26) | 1.10 (28) | 1.26 (32) | | | 1.10 (28) | 1.26 (32) | 1.42 (36) |

| Injection capacity | inch3 (cm3) (oz) | 2.1 (35) (1.2) | 3.0 (49) (1.6) | 3.5 (57) (1.9) | | | 3.6 (59) (2.0) | 4.2 (69) (2.3) | 5.5 (90) (3.0) | | | 4.7 (77) (2.6) | 6.2 (101) (3.4) | 7.7 (127) (4.3) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 40630 (280) (2857) | 28440 (196) (2000) | 24520 (169) (1724) | | | 40630 (280) (2857) | 35260 (243) (2480) | 26990 (186) (1898) | | | 40630 (280) (2857) | 32360 (223) (2276) | 25680 (177) (1806) |

| Clamping force | USton (kN) (tf) |

154 (1370) (140) |

||||||||||

| Clamping stroke | inch (mm) |

15.7 (400) |

||||||||||

| Mold thickness (min.-max.) | inch (mm) |

6.7~17.7 (170~450) |

||||||||||

| Max. daylight opening | inch (mm) |

33.5 (850) |

||||||||||

| Tie bar clearance (H×V) | inch (mm) |

26.0x14.2 (660x360) |

||||||||||

| Die plate dimensions (H×V) | inch (mm) |

33.9x21.7 (860x550) |

||||||||||

| Ejector stroke | inch (mm) |

3.9 (100) |

||||||||||

| Item | Unit | 9E (A: 9E & B: 9E)* | | | 12E (A: 12E & B: 12E)* | | | 18E (A: 18E & B: 18E) | | | 25E (A: 25E & B: 25E) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Screw diameter | inch (mm) | 1.02 (26) | 1.10 (28) | 1.26 (32) | | | 1.10 (28) | 1.26 (32) | 1.42 (36) | | | 1.26 (32) | 1.42 (36) | 1.57 (40) | | | 1.42 (36) | 1.57 (40) | 1.77 (45) |

| Injection capacity | inch3 (cm3) (oz) | 3.6 (59) (2.0) | 4.2 (69) (2.3) | 5.5 (90) (3.0) | | | 4.7 (77) (2.6) | 6.2 (101) (3.4) | 7.7 (127) (4.3) | | | 7.1 (117) (3.9) | 9.0 (148) (5.0) | 11.1 (182) (6.1) | | | 9.9 (163) (5.5) | 12.3 (201) (6.7) | 15.5 (254) (8.5) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 40630 (280) (2857) | 35260 (243) (2480) | 26990 (186) (1898) | | | 40630 (280) (2857) | 32360 (223) (2280) | 25690 (177) (1806) | | | 40050 (276) (2816) | 31630 (218) (2224) | 25690 (177) (1806) | | | 38870 (261) (2663) | 30620 (211) (2153) | 24230 (167) (1704) |

| Clamping force |

USton (kN) (tf) |

275 (2450) (250) |

||||||||||||||

| Clamping stroke |

inch (mm) |

22.0 (560) |

||||||||||||||

| Mold thickness (min.-max.) |

inch (mm) |

9.8~22.0 (250~560) |

||||||||||||||

| Max. daylight opening |

inch (mm) |

44.1 (1120) |

||||||||||||||

| Tie bar clearance (H×V) |

inch (mm) |

37.8x20.5 (960x520) |

||||||||||||||

| Die plate dimensions (H×V) |

inch (mm) |

48.4x30.7 (1230x780) |

||||||||||||||

| Ejector stroke |

inch (mm) |

3.9 (100) |

||||||||||||||

● Specifications apply to U.S. machines only.

● All specs and dimensions are subject to change without notice or may differ depending on export destinations and manufactured year.

● NISSEI is not responsible for any inaccuracies contained herein.

● Please consult our sales representative or NISSEI regional offices before designing a mold.

● Actual plasticizing capacity may vary, depending on the molding conditions and material used.

● Injection unit: operator side=A and non-operator side=B

*Special order