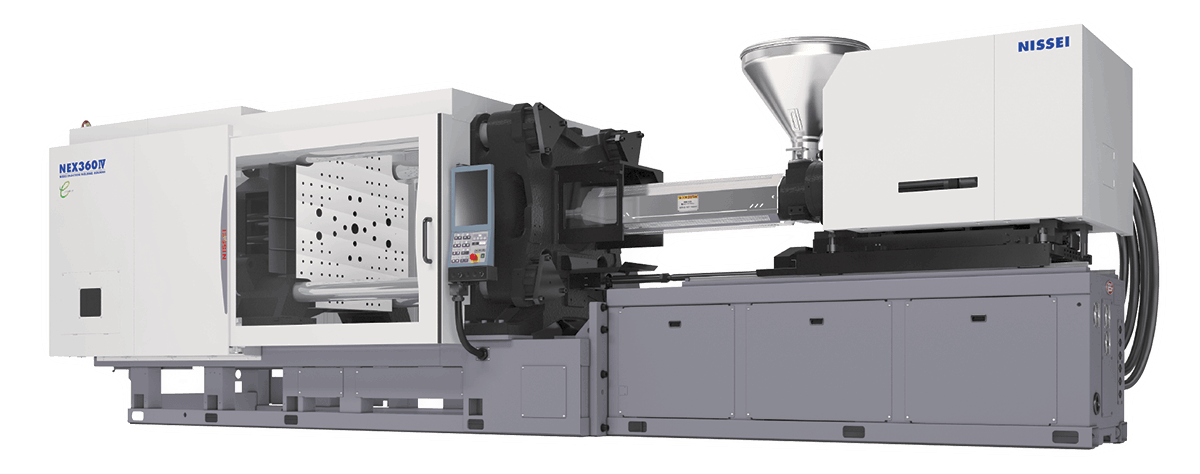

NEX-Ⅳ Series

ALL-ELECTRIC INJECTION MOLDING MACHINE

Clamping force: 30~360 ton (33~397 USton)

- All-Electric

- Horizontal

- Linear Pressure Toggle

- General-Purpose

- TACT® Ⅳ Controller

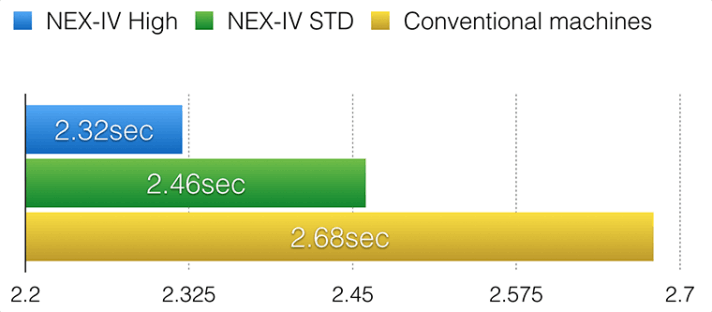

The newly-designed toggle mechanism can cut the mold open/close cycle time by 5~20%, and the ejector speed is up to 19% quicker compared to the conventional type machines, increasing productivity. The time-tested "Flat Clamp Mechanism" has been further developed. "The New Flat Clamp Mechanism" improves the evenness of its contact pressure and prolongs the service life of the mold and clamping unit. To improve clamping precision, linear guides come standard for clamping slides, which improve the rectilinearity of the clamp and contribute to prevent molding defects. Combining it with the "Precision Metering" function, which maintains the consistency of metering density and injection volume, it materializes highly-stable precision molding with high repeatability.

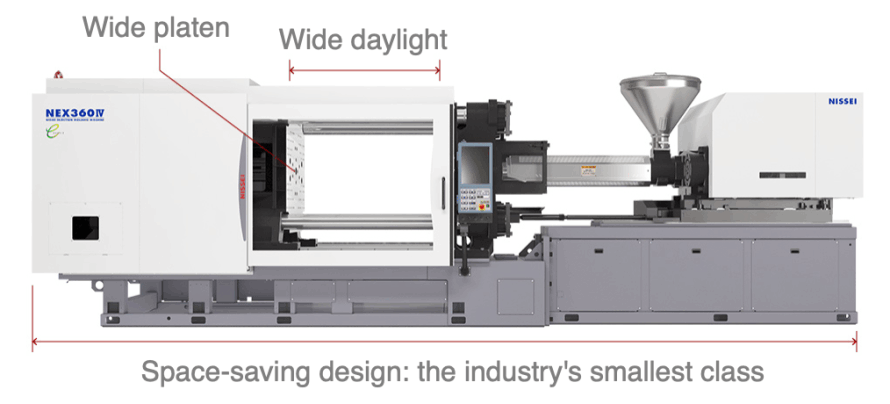

NEX-Ⅳ Series offers one of the widest daylights in the industry while keeping its footprints to industry's smallest size. By adding 70~140mm to the daylights, the mold thickness ranges have been greatly increased. It flexibly accommodates hot runner molds, molds for long-length products, and modern molds which grow in size in accordance with integral molding or intricate shapes of the products. In addition, die plate dimensions, tie bar clearances, and maximum movable side mold weights have been greatly increased; expanding mountable mold sizes (up to 40% larger than the conventional types). In conjunction with the low-pressure molding method "K-SAPLI," which eliminates molding defects and prolongs the life of the mold by lowering the clamping force to the optimum level, one class smaller injection molding machine can be selected and used for an existing mold (one-class downsizing).

| Item | Unit | 2EG | | | 3EG | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Screw diameter | inch (mm) | A 0.63 (16) | B 0.75 (19) | | | A 0.75 (19) | B 0.87 (22) | ||||

| Injection capacity | inch3 (cm3) (oz) | 0.8 (13) (0.4) | 1.1 (18) (0.6) | | | 1.4 (23) (0.8) | 2.1 (35) (1.2) | ||||

| Max. injection pressure | psi (MPa) (kgf/cm2) | 38450 (265) (2704) | 28440 (196) (2000) | | | 38450 (265) (2704) | 30470 (210) (2143) | ||||

| Clamping force | USton (kN) (tf) |

33 (294) (30) |

||||||||

| Clamping stroke | inch (mm) |

9.06 (230) |

||||||||

| Mold thickness (min-max) | inch (mm) |

5.91~14.8 (150~375) |

||||||||

| Max. daylight opening | inch (mm) |

23.8 (605) |

||||||||

| Tie bar clearance (H×V) | inch (mm) |

12.2x12.2 (310x310) |

||||||||

| Die plate dimensions (H×V) | inch (mm) |

17.7x17.7 (450x450) |

||||||||

| Ejector stroke | inch (mm) |

1.97 (50) |

||||||||

| Item | Unit | 3EG | | | 5EG |

|||

|---|---|---|---|---|---|---|---|

| Screw diameter | inch (mm) | A 0.75 (19) | B 0.87 (22) | | | A 0.87 (22) | B 1.02 (26) | BB 1.10 (28) |

| Injection capacity | inch3 (cm3) (oz) | 1.4 (23) (0.8) | 2.1 (35) (1.2) | | | 2.1 (35) (1.2) | 3.0 (49) (1.6) | 3.5 (57) (1.9) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 38450 (265) (2704) | 30470 (210) (2143) | | | 40630 (280) (2857) | 28440 (196) (2000) | 24520 (169) (1725) |

| Clamping force | USton (kN) (tf) |

55 (490) (50) |

|||||

| Clamping stroke | inch (mm) |

9.84 (250) |

|||||

| Mold thickness (min.-max.) | inch (mm) |

5.91~18.1 (150~460) |

|||||

| Max. daylight opening | inch (mm) |

28.0 (710) |

|||||

| Tie bar clearance (H×V) | inch (mm) |

14.2x14.2 (360x360) |

|||||

| Die plate dimensions (H×V) | inch (mm) |

19.9x19.9 (505x505) |

|||||

| Ejector stroke | inch (mm) |

2.95 (75) |

|||||

| Item | Unit | 5EG | | | 9EG | | | 12EG | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Screw diameter | inch (mm) | A 0.87 (22) | B 1.02 (26) | BB 1.10 (28) | | | AA 1.02 (26) | A 1.10 (28) | B 1.26 (32) | | | AA 1.10 (28) | A 1.26 (32) | B 1.42 (36) |

| Injection capacity | inch3 (cm3) (oz) | 2.1 (35) (1.2) | 3.0 (49) (1.6) | 3.5 (57) (1.9) | | | 3.3 (54) (1.8) | 4.2 (69) (2.3) | 5.5 (90) (3.0) | | | 4.2 (69) (2.3) | 6.2 (101) (3.4) | 7.7 (127) (4.3) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 40630 (280) (2857) | 28440 (196) (2000) | 24520 (169) (1725) | | | 40630 (280) (2857) | 35260 (243) (2480) | 26990 (186) (1898) | | | 40630 (280) (2857) | 32360 (223) (2276) | 25680 (177) (1806) |

| Clamping force | USton (kN) (tf) |

88 (784) (80) |

||||||||||

| Clamping stroke | inch (mm) |

11.8 (300) |

||||||||||

| Mold thickness (min.-max.) | inch (mm) |

5.91~19.1 (150~485) |

||||||||||

| Max. daylight opening | inch (mm) |

30.9 (785) |

||||||||||

| Tie bar clearance (H×V) | inch (mm) |

16.5x16.5 (420x420) |

||||||||||

| Die plate dimensions (H×V) | inch (mm) |

22.8x22.8 (580x580) |

||||||||||

| Ejector stroke | inch (mm) |

2.95 (75) |

||||||||||

| Item | Unit | 9EG | | | 12EG | | | 18E | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Screw diameter | inch (mm) | AA 1.02 (26) | A 1.10 (28) | B 1.26 (32) | | | AA 1.10 (28) | A 1.26 (32) | B 1.42 (36) | | | AA 1.26 (32) | A 1.42 (36) | B 1.57 (40) |

| Injection capacity | inch3 (cm3) (oz) | 3.3 (54) (1.8) | 4.2 (69) (2.3) | 5.5 (90) (3.0) | | | 4.2 (69) (2.3) | 6.2 (101) (3.4) | 7.8 (127) (4.3) | | | 7.1 (117) (3.9) | 9.0 (148) (5.0) | 11.1 (182) (6.1) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 40630 (280) (2857) | 35260 (243) (2480) | 26990 (186) (1898) | | | 40630 (280) (2857) | 32360 (223) (2276) | 25680 (177) (1806) | | | 40050 (276) (2816) | 31630 (218) (2225) | 25680 (177) (1806) |

| Clamping force | USton (kN) (tf) |

121 (1080) (110) |

||||||||||

| Clamping stroke | inch (mm) |

13.8 (350) |

||||||||||

| Mold thickness (min.-max.) | inch (mm) |

7.09~20.1 (180~510) |

||||||||||

| Max. daylight opening | inch (mm) |

33.9 (860) |

||||||||||

| Tie bar clearance (H×V) | inch (mm) |

18.1x18.1 (460x460) |

||||||||||

| Die plate dimensions (H×V) | inch (mm) |

25.5x25.5 (647x647) |

||||||||||

| Ejector stroke | inch (mm) |

3.94 (100) |

||||||||||

| Item | Unit | 12EG | | | 18E | | | 25E | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Screw diameter | inch (mm) | AA 1.10 (28) | A 1.26 (32) | B 1.42 (36) | | | AA 1.26 (32) | A 1.42 (36) | B 1.57 (40) | | | AA 1.42 (36) | A 1.57 (40) | B 1.7 (45) |

| Injection capacity | inch3 (cm3) (oz) | 4.2 (69) (2.3) | 6.2 (101) (3.4) | 7.7 (127) (4.3) | | | 7.1 (117) (3.9) | 9.0 (148) (5.0) | 11.1 (182) (6.1) | | | 9.9 (163) (5.5) | 12.3 (201) (6.7) | 15.5 (254) (8.5) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 40630 (280) (2857) | 32360 (223) (2276) | 25680 (177) (1806) | | | 40050 (276) (2816) | 31630 (218) (2225) | 25680 (177) (1806) | | | 37870 (261) (2663) | 30620 (211) (2153) | 24230 (167) (1704) |

| Clamping force | USton (kN) (tf) |

154 (1373) (140) |

||||||||||

| Clamping stroke | inch (mm) |

15.7 (400) |

||||||||||

| Mold thickness (min.-max.) | inch (mm) |

7.09~21.7 (180~550) |

||||||||||

| Max. daylight opening | inch (mm) |

37.4 (950) |

||||||||||

| Tie bar clearance (H×V) | inch (mm) |

20.1x20.1 (510x510) |

||||||||||

| Die plate dimensions (H×V) | inch (mm) |

28.3x28.3 (720x720) |

||||||||||

| Ejector stroke | inch (mm) |

4.72 (120) |

||||||||||

| Item | Unit | 18E | | | 25E | | | 36E | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Screw diameter | inch (mm) | AA 1.26 (32) | A 1.42 (36) | B 1.57 (40) | | | AA 1.42 (36) | A 1.57 (40) | B 1.77 (45) | | | AA 1.57 (40) | A 1.77 (45) | B 1.97 (50) |

| Injection capacity | inch3 (cm3) (oz) | 7.1 (117) (3.9) | 9.0 (148) (5.0) | 11.1 (182) (6.1) | | | 9.95 (163) (5.5) | 12.3 (201) (6.7) | 15.5 (254) (8.5) | | | 13.8 (226) (7.6) | 17.5 (286) (9.6) | 21.5 (353) (11.8) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 40050 (276) (2816) | 31620 (218) (2224) | 25680 (177) (1806) | | | 37870 (261) (2663) | 30620 (211) (2153) | 24230 (167) (1704) | | | 37730 (260) (2653) | 29890 (206) (2102) | 24230 (167) (1704) |

| Clamping force | USton (kN) (tf) |

198 (1765) (180) |

||||||||||

| Clamping stroke | inch (mm) |

17.7 (450) |

||||||||||

| Mold thickness (min.-max.) | inch (mm) |

6.89~23.0 (175~585) |

||||||||||

| Max. daylight opening | inch (mm) |

40.7 (1035) |

||||||||||

| Tie bar clearance (H×V) | inch (mm) |

22.0x22.0 (560x560) |

||||||||||

| Die plate dimensions (H×V) | inch (mm) |

31.5x31.5 (800x800) |

||||||||||

| Ejector stroke | inch (mm) |

5.91 (150) |

||||||||||

| Item | Unit | 50E | | | 71E |

||||

|---|---|---|---|---|---|---|---|---|

| Screw diameter | inch (mm) | AA 1.77 (45) | A 1.97 (50) | B 2.20 (56) | | | AA 1.97 (50) | A 2.20 (56) | B 2.48 (63) |

| Injection capacity | inch3 (cm3) (oz) | 19.9 (326) (10.9) | 24.6 (403) (13.5) | 30.8 (505) (16.9) | | | 27.0 (442) (14.8) | 33.8 (554) (18.6) | 42.8 (701) (23.5) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 36280 (250) (2551) | 29310 (202) (2061) | 23360 (161) (1643) | | | 36130 (249) (2541) | 28880 (199) (2031) | 22780 (157) (1602) |

| Clamping force | USton (kN) (tf) |

243 (2160) (220) |

||||||

| Clamping stroke | inch (mm) |

21.7 (550) |

||||||

| Mold thickness (min.-max.) | inch (mm) |

10.8~26.8 (275~680) |

||||||

| Max. daylight opening | inch (mm) |

48.4 (1230) |

||||||

| Tie bar clearance (H×V) | inch (mm) |

26.0x24.0 (660x610) |

||||||

| Die plate dimensions (H×V) | inch (mm) |

36.2x34.3 (920x870) |

||||||

| Ejector stroke | inch (mm) |

5.91 (150) |

||||||

| Item | Unit | 71E | | | 100LE |

||||

|---|---|---|---|---|---|---|---|---|

| Screw diameter | inch (mm) | AA 1.97 (50) | A 2.20 (56) | B 2.48 (63) | | | AA 1.97 (50) | A 2.20 (56) | B 2.48 (63) |

| Injection capacity | inch3 (cm3) (oz) | 27.0 (442) (14.8) | 33.8 (554) (18.6) | 42.8 (701) (23.5) | | | 33.6 (550) (18.4) | 47.4 (776) (26.0) | 59.9 (982) (32.9) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 36130 (249) (2541) | 28880 (199) (2031) | 22780 (157) (1602) | | | 36130 (249) (2541) | 28880 (199) (2031) | 22780 (157) (1602) |

| Clamping force | USton (kN) (tf) |

308 (2740) (280) |

||||||

| Clamping stroke | inch (mm) |

23.6 (600) |

||||||

| Mold thickness (min.-max.) | inch (mm) |

11.8~29.5 (300~750) |

||||||

| Max. daylight opening | inch (mm) |

53.1 (1350) |

||||||

| Tie bar clearance (H×V) | inch (mm) |

29.9x26.0 (760x660) |

||||||

| Die plate dimensions (H×V) | inch (mm) |

41.5x37.6 (1055x955) |

||||||

| Ejector stroke | inch (mm) |

5.91 (150) |

||||||

| Item | Unit | 100LE | ||

|---|---|---|---|---|

| Screw diameter | inch (mm) | AA 1.97 (50) | A 2.20 (56) | B 2.48 (63) |

| Injection capacity | inch3 (cm3) (oz) | 33.6 (550) (18.4) | 47.4 (776) (26.0) | 59.9 (982) (32.9) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 36130 (249) (2541) | 28880 (199) (2031) | 22780 (157) (1602) |

| Clamping force | USton (kN) (tf) |

397 (3530) (360) |

||

| Clamping stroke | inch (mm) |

25.6 (650) |

||

| Mold thickness (min.-max.) | inch (mm) |

11.8x31.1 (300~790) |

||

| Max. daylight opening | inch (mm) |

56.7 (1440) |

||

| Tie bar clearance (H×V) | inch (mm) |

31.9x29.9 (810x760) |

||

| Die plate dimensions (H×V) | inch (mm) |

44.5x42.5 (1130x1080) |

||

| Ejector stroke | inch (mm) |

7.87 (200) |

||

● Specifications apply to U.S. machines only.

● All specs and dimensions are subject to change without notice or may differ depending on export destinations and manufactured year.

● NISSEI is not responsible for any inaccuracies contained herein.

● Please consult our sales representative or NISSEI regional offices before designing a mold.

● Actual plasticizing capacity may vary, depending on the molding conditions and material used.