TH-EⅢ Series

ALL-ELECTRIC VERTICAL INJECTION MOLDING MACHINE

Clamping force: 20~80 ton (22~88 USton)

- All-Electric

- Vertical

- Single-Stage Type

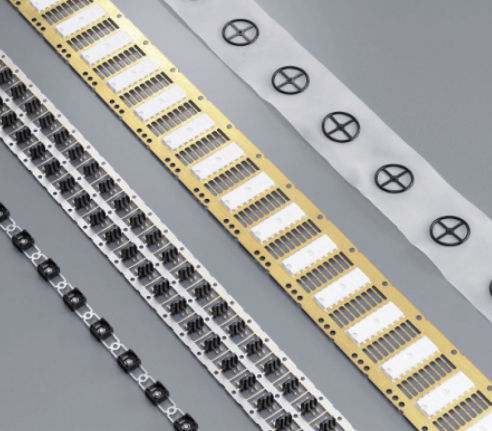

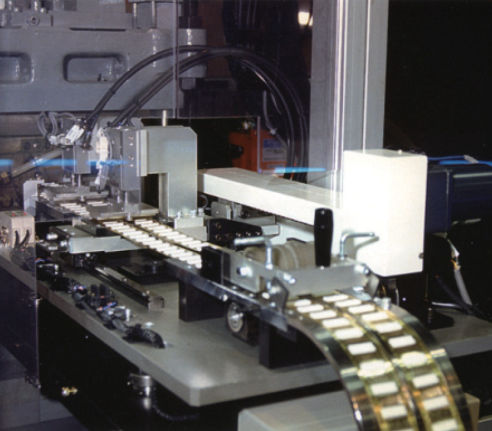

- Ideal for Thin-Hoop Molding

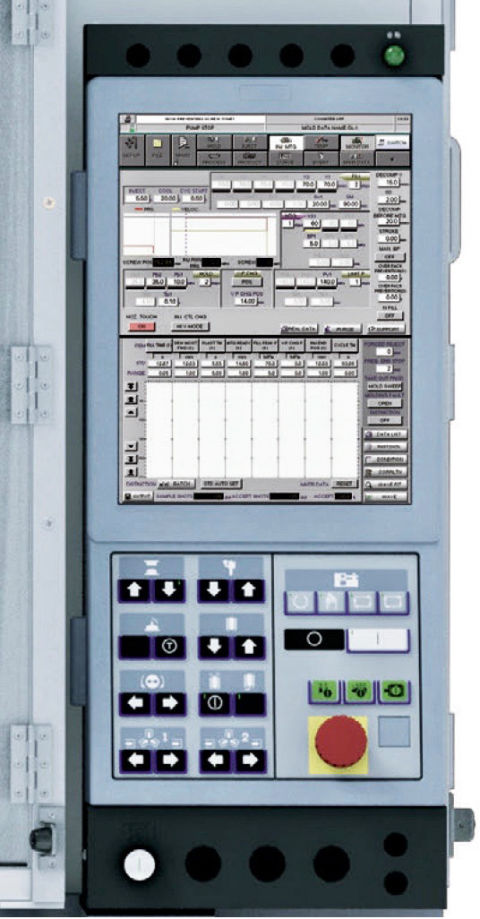

- TACT® Ⅳ Controller

Electric vertical injection molding machine TH-E Series is ideal for high-cycle thin hoop molding. It is equipped with a high-performance/high-functioning TACT® Ⅳ Controller, taking its convenience and user-friendliness to a whole new level. It offers the advantages of electric type machines backed by NISSEI's abundant experience in time-tested hydraulic type vertical injection molding machines and further-evolved TACT® Ⅳ Controller. It materializes excellent workability, operability, energy-efficiency, clean performance, high-precision control, and high-cycle molding.

Larger screen, newly designed operation panel, and convenient & user-friendly premium software are equipped to improve workability & operability, and the quality & production management functions have been reinforced.

Sheet switch type is used for the operation panel, and 15-inch vertical LCD can arrange two windows vertically, materializing superior visibility and operability.

Molding condition settings to increase yield, which used to require a skilled technician, are automated and simplified. Its "Easy Setting" permits the reduction of defect rate.

In addition, new features, such as SET-UP screen and display of the descriptions of adjusters, allow saving of preparation time from mold installation to starting of mass production and materialization of easy & reliable operation.

| Item | Unit | 2VE | ||

|---|---|---|---|---|

| Screw diameter | inch (mm) | 0.63 (16) | 0.75 (19) | |

| Injection capacity | inch3 (cm3) (oz) | 0.8 (13) (0.4) | 1.1 (18) (0.6) | |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 36970 (255) (2600) | 28440 (196) (2000) | |

| Clamping force | USton (kN) (tf) |

22 (196) (20) |

||

| Clamping stroke | inch (mm) |

7.9 (200) |

||

| Mold thickness (min-max) | inch (mm) |

6.7~10.6 (170~270) |

||

| Max. daylight opening | inch (mm) |

18.5 (470) |

||

| Tie bar clearance (H×V) | inch (mm) |

12.2x12.2 (310x310) |

||

| Die plate dimensions (H×V) | inch (mm) |

18.1x18.1 (460x460) |

||

| Ejector stroke | inch (mm) |

1.6 (40) |

||

| Item | Unit | 5VE | ||

|---|---|---|---|---|

| Screw diameter | inch (mm) | 0.75 (19) | 0.87 (22) | 1.02 (26) |

| Injection capacity | inch3 (cm3) (oz) | 1.4 (23) (0.8) | 2.1 (35) (1.2) | 3.0 (49) (1.6) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 38400 (265) (2700) | 36970 (255) (2600) | 28440 (196) (2000) |

| Clamping force | USton (kN) (tf) |

44 (392) (40) |

||

| Clamping stroke | inch (mm) |

9.4 (240) |

||

| Mold thickness (min-max) | inch (mm) |

9.5~11.4 (190~290) |

||

| Max. daylight opening | inch (mm) |

20.9 (530) |

||

| Tie bar clearance (H×V) | inch (mm) |

14.2x14.2 (360x360) |

||

| Die plate dimensions (H×V) | inch (mm) |

20.5x20.5 (520x520) |

||

| Ejector stroke | inch (mm) |

1.6 (40) |

||

| Item | Unit | 5VE | | | 9VE | |||

|---|---|---|---|---|---|---|---|

| Screw diameter | inch (mm) | 0.75 (19) | 0.87 (22) | 1.02 (26) | | | 1.10 (28) | 1.26 (32) |

| Injection capacity | inch3 (cm3) (oz) | 1.4 (23) (0.8) | 2.1 (35) (1.2) | 3.0 (49) (1.6) | | | 4.2 (69) (2.3) | 5.5 (90) (3.0) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 38400 (265) (2700) | 36970 (255) (2600) | 28440 (196) (2000) | | | 35270 (243) (2480) | 27020 (186) (1900) |

| Clamping force | USton (kN) (tf) |

77 *(88) (686) *(784) (70) *(80) |

|||||

| Clamping stroke | inch (mm) |

9.8 (250) |

|||||

| Mold thickness (min-max) | inch (mm) |

9.1~13.8 (230~350) |

|||||

| Max. daylight opening | inch (mm) |

23.6 (600) |

|||||

| Tie bar clearance (H×V) | inch (mm) |

16.5x16.5 (420x420) |

|||||

| Die plate dimensions (H×V) | inch (mm) |

23.9x23.9 (607x607) |

|||||

| Ejector stroke | inch (mm) |

2.4 (60) |

|||||

● Specifications apply to U.S. machines only.

● All specs and dimensions are subject to change without notice or may differ depending on export destinations and manufactured year.

● NISSEI is not responsible for any inaccuracies contained herein.

● Please consult our sales representative or NISSEI regional offices before designing a mold.

● Actual plasticizing capacity may vary, depending on the molding conditions and material used.

● Clamping force of TH70EⅢ can be increased to 784kN (80tf) (optional).