DCX-III Series

HYBRID TYPE 2-COLOR/DISSIMILAR MATERIAL IMM

Clamping force: 121~813 ton (134~896 USton)

- Hybrid

- Horizontal

- 2-Piston Mold Clamping System

- Double Injection

- TACT® Ⅳ Controller

- X-Pump® System

DCX-Ⅲ Series is equipped with NISSEI's original 2-piston type clamping mechanism, which transmits ideal clamping force to both sides of molds. High-performance High-functioning controller TACT® Ⅳ achieves faster control and improves repeatability. The newly-developed servo-driven rotation mechanism achieves high-speed and shockless mold reversing motion (reversing time: about 1/2 of the conventional machines).

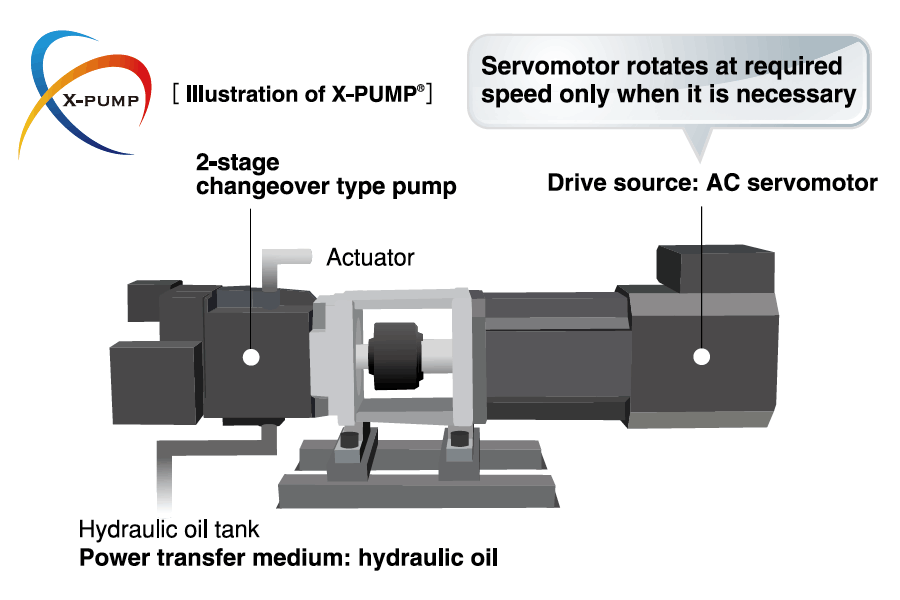

"Fusion of Hydraulic Control and Servomotor Drive Technologies"

The X-Pump System merges NISSEI’s time-tested hydraulic technologies with cutting-edge servomotor drive systems. Since the servomotor operates at required speed on demand, the X-Pump System delivers super energy efficient performance.

In addition, its exceptional injection repeatability and low velocity/pressure controllability make production of higher precision and quality products possible.

| Item | Unit | 9A (A: 9A & B: 9A) | |||

|---|---|---|---|---|---|

| Screw diameter | inch (mm) | 1.02 (26) | 1.10 (28) | 1.26 (32) | 1.42 (36) |

| Injection capacity | inch3 (cm3) (oz) | 3.6 (59) (2.0) | 4.2 (69) (2.3) | 5.5 (90) (3.0) | 7.0 (114) (3.8) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 38450 (265) (2704) | 35410 (244) (2490) | 27140 (187) (1908) | 21330 (147) (1500) |

| Clamping force | USton (kN) (tf) |

134 (1190) (121) |

|||

| Clamping stroke | inch (mm) |

17.7 (450) |

|||

| Min. mold thickness | inch (mm) |

6.7 (170) |

|||

| Max. daylight opening | inch (mm) |

24.4 (620) |

|||

| Tie bar clearance (H×V) | inch (mm) |

26.0x9.8 (660x250) |

|||

| Die plate dimensions (H×V) | inch (mm) |

31.5x18.9 (800x480) |

|||

| Ejector stroke | inch (mm) |

3.9 (100) |

|||

| Item | Unit | 25A (A: 25A & B: 25A) | |||

|---|---|---|---|---|---|

| Screw diameter | inch (mm) | 1.42 (36) | 1.57 (40) | 1.77 (45) | 1.97 (50) |

| Injection capacity | inch3 (cm3) (oz) | 9.95 (163) (5.5) | 12.3 (201) (6.7) | 15.5 (254) (8.5) | 19.2 (314) (10.5) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 37000 (255) (2602) | 31780 (219) (2235) | 25100 (173) (1765) | 20320 (140) (1429) |

| Clamping force | USton (kN) (tf) |

224 (1990) (203) |

|||

| Clamping stroke | inch (mm) |

20.5 (520) |

|||

| Min. mold thickness | inch (mm) |

9.8 (250) |

|||

| Max. daylight opening | inch (mm) |

30.3 (770) |

|||

| Tie bar clearance (H×V) | inch (mm) |

36.4x12.0 (925x305) |

|||

| Die plate dimensions (H×V) | inch (mm) |

42.1x22.4 (1070x570) |

|||

| Ejector stroke | inch (mm) |

3.9 (100) |

|||

| Item | Unit | 36A (A: 36A & B: 36A) | ||

|---|---|---|---|---|

| Screw diameter | inch (mm) | 1.77 (45) | 1.97 (50) | 2.20 (56) |

| Injection capacity | inch3 (cm3) (oz) | 17.5 (286) (9.6) | 21.5 (353) (11.8) | 27.0 (443) (14.8) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 30040 (207) (2112) | 24380 (168) (1714) | 19450 (134) (1367) |

| Clamping force | USton (kN) (tf) |

446 (3970) (405) |

||

| Clamping stroke | inch (mm) |

29.5 (750) |

||

| Min. mold thickness | inch (mm) |

11.8 (300) |

||

| Max. daylight opening | inch (mm) |

41.3 (1050) |

||

| Tie bar clearance (H×V) | inch (mm) |

44.1x16.5 (1120x420) |

||

| Die plate dimensions (H×V) | inch (mm) |

53.5x31.9 (1360x810) |

||

| Ejector stroke | inch (mm) |

4.7 (120) |

||

| Item | Unit | 50A (A: 50A & B: 50A) | ||

|---|---|---|---|---|

| Screw diameter | inch (mm) | 1.97 (50) | 2.20 (56) | 2.48 (63) |

| Injection capacity | inch3 (cm3) (oz) | 24.5 (402) (13.5) | 30.8 (505) (16.9) | 39.0 (639) (21.4) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 28730 (198) (2020) | 22930 (158) (1612) | 18140 (125) (1276) |

| Clamping force | USton (kN) (tf) |

661 (5880) (600) |

||

| Clamping stroke | inch (mm) |

33.5 (850) |

||

| Min. mold thickness | inch (mm) |

17.7 (450) |

||

| Max. daylight opening | inch (mm) |

51.2 (1300) |

||

| Tie bar clearance (H×V) | inch (mm) |

59.6x22.2 (1515x565) |

||

| Die plate dimensions (H×V) | inch (mm) |

72.0x40.6 (1830x1030) |

||

| Ejector stroke | inch (mm) |

7.1 (180) |

||

| Item | Unit | 71A (A: 71A & B: 71A) | ||

|---|---|---|---|---|

| Screw diameter | inch (mm) | 2.20 (56) | 2.48 (63) | 2.80 (71) |

| Injection capacity | inch3 (cm3) (oz) | 33.8 (554) (18.6) | 42.8 (701) (23.5) | 54.4 (891) (29.9) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 28440 (196) (2000) | 22490 (155) (1582) | 17700 (122) (1245) |

| Clamping force | USton (kN) (tf) |

896 (7965) (813) |

||

| Clamping stroke | inch (mm) |

40.4 (1025) |

||

| Min. mold thickness | inch (mm) |

17.7 (450) |

||

| Max. daylight opening | inch (mm) |

58.1 (1475) |

||

| Tie bar clearance (H×V) | inch (mm) |

73.6x28.0 (1870x710) |

||

| Die plate dimensions (H×V) | inch (mm) |

85.4x47.2 (2170x1200) |

||

| Ejector stroke | inch (mm) |

7.9 (200) |

||

● Specifications apply to U.S. machines only.

● All specs and dimensions are subject to change without notice or may differ depending on export destinations and manufactured year.

● NISSEI is not responsible for any inaccuracies contained herein.

● Please consult our sales representative or NISSEI regional offices before designing a mold.

● Actual plasticizing capacity may vary, depending on the molding conditions and material used.

● Injection unit: operator side=A and non-operator side=B