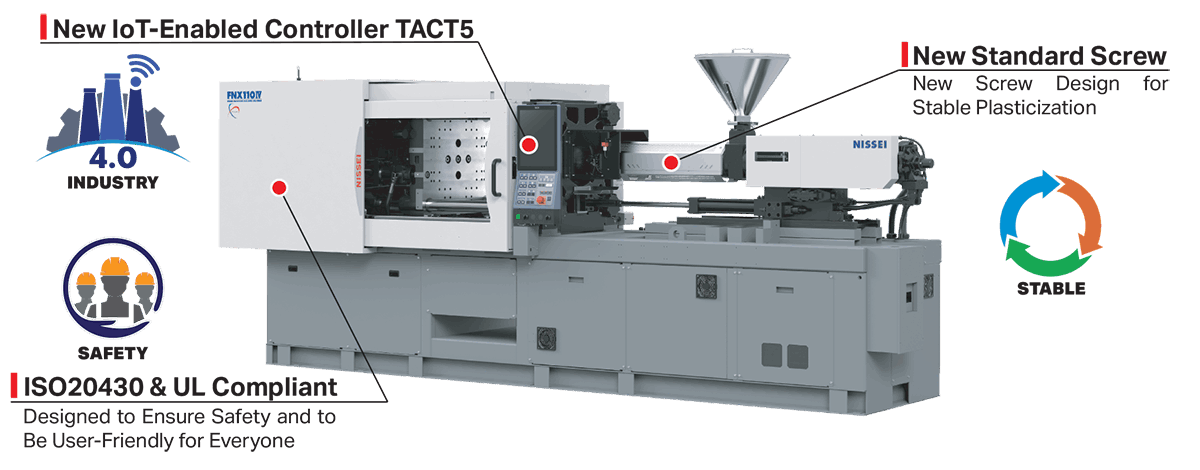

FNX-Ⅳ Series

HYBRID TYPE INJECTION MOLDING MACHINE

Clamping force: 81~455 ton (89~501 USton)

- Hybrid (Mid-Size)

- Horizontal

- Direct Pressure Clamping

- IoT-Enabeld TACT® 5 Controller

- X-Pump System®

NISSEI’s new IoT technology “N-constellation™” materializes the injection molding machine to function as a network hub to connect various auxiliary equipment. It allows real-time collection of operation data, remote monitoring, and remote maintenance as well as offering predictive maintenance feature in the future. The all-new FNX-Ⅳ Series leads the future of injection molding machines.

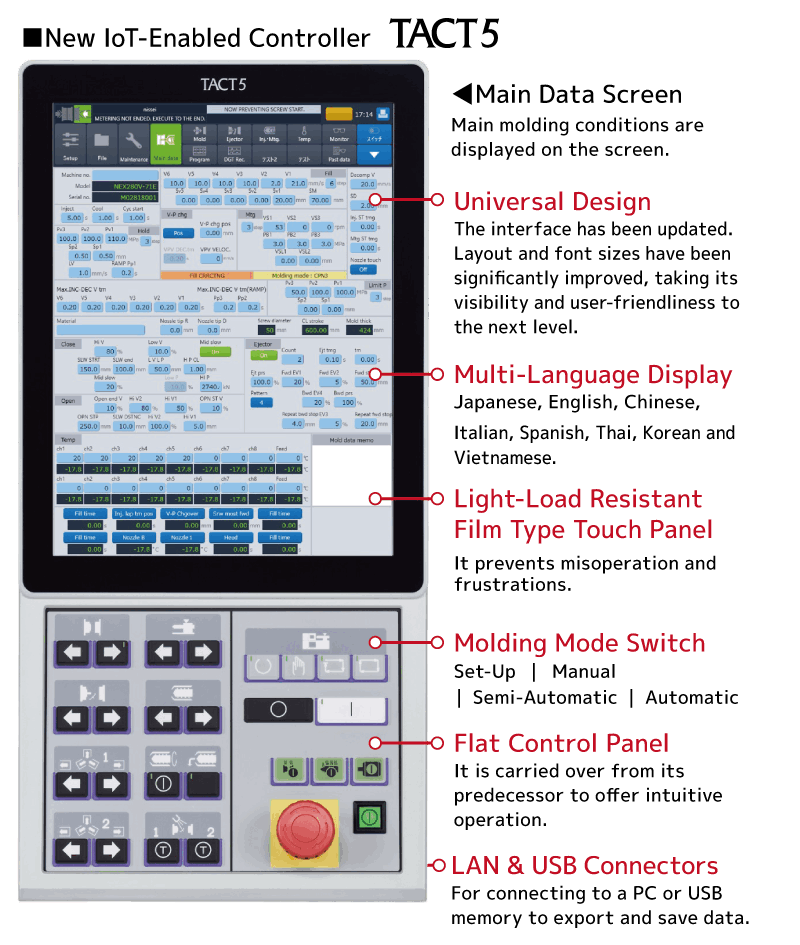

New IoT-Enabled Controller "TACT5"

Universal Safety Standard

“ISO20430” Compliant

New Standard Screw that Improves

Plasticization

Uniform Clamping Force Transmission

Clamping Force Reduction

Smooth Mold Open/Close Motion

Electric Machine Level of Energy Efficiency

Superior Grease-Free Clean Performance

Exceptional Longevity and Maintainability

"Supporting Digital Transformation (DX) of Injection Molding Machines"

FNX-Ⅳ Series can function as a hub, which connects devices and equipment in a factory. By visualizing the operation status of each device and collaborating with other equipment and people, an efficient smart factory can be materialized. FNX-Ⅳ Series machines are newly designed to make molding operation intuitive for both current NISSEI users and first-time users.

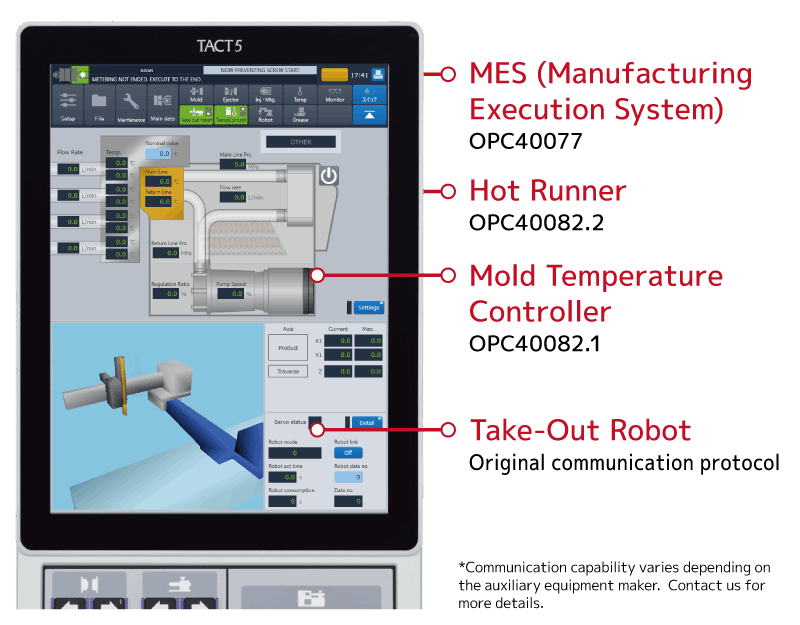

"To Be a Hub for the Molding Factory"

OPC-UA, which is a communication standard widely used throughout the world to network controllers, comes standard in FNX-IV Series. The machine, various auxiliary equipment, and MES can be networked. Data collected in the molding machine can be displayed on TACT screen.

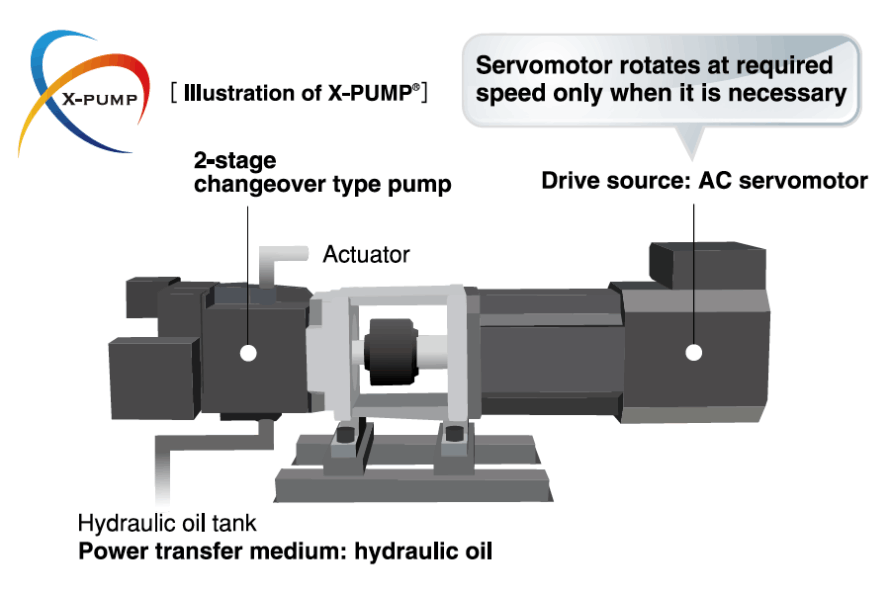

"Fusion of Hydraulic Control and Servomotor Drive Technologies"

The X-Pump System merges NISSEI’s time-tested hydraulic technologies with cutting-edge servomotor drive systems. Since the servomotor operates at required speed on demand, the X-Pump System delivers super energy efficient performance.

In addition, its exceptional injection repeatability and low velocity/pressure controllability make production of higher precision and quality products possible.

| Item | Unit | 9A (std) | | | 12A | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Screw diameter | inch (mm) | AA 1.02 (26) | A 1.10 (28) | B 1.26 (32) | C 1.42 (36) | | | AA 1.10 (28) | A 1.26 (32) | B 1.42 (36) | C 1.57 (40) |

| Injection capacity | inch3 (cm3) (oz) | 3.6 (59) (2.0) | 4.2 (69) (2.3) | 5.5 (90) (3.0) | 7.0 (114) (3.8) | | | 4.7 (77) (2.6) | 6.2 (101) (3.4) | 7.7 (127) (4.3) | 9.6 (157) (5.3) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 38470 (265) (2705) | 35410 (244) (2490) | 27160 (187) (1910) | 21330 (147) (1500) | | | 38470 (265) (2705) | 32850 (226) (2310) | 26020 (179) (1830) | 21050 (145) (1480) |

| Clamping force | USton (kN) (tf) |

89 (792) (81) |

||||||||

| Clamping stroke | inch (mm) |

18.5 (470) |

||||||||

| Min. mold thickness | inch (mm) |

7.9 (200) |

||||||||

| Max. daylight opening | inch (mm) |

26.4 (670) |

||||||||

| Tie bar clearance (H×V) | inch (mm) |

16.5x16.5 (420x420) |

||||||||

| Die plate dimensions (H×V) | inch (mm) |

22.8x22.8 (580x580) |

||||||||

| Ejector stroke | inch (mm) |

3.0 (75) |

||||||||

| Item | Unit | 12A (std) | | | 18A | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Screw diameter | inch (mm) | AA 1.10 (28) | A 1.26 (32) | B 1.42 (36) | C 1.57 (40) | | | AA 1.26 (32) | A 1.42 (36) | B 1.57 (40) | C 1.77 (45) |

| Injection capacity | inch3 (cm3) (oz) | 4.7 (77) (2.6) | 6.2 (101) (3.4) | 7.7 (127) (4.3) | 9.6 (157) (5.3) | | | 7.1 (117) (3.9) | 9.0 (147) (4.9) | 11.1 (182) (6.1) | 14.1 (231) (7.7) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 38470 (265) (2700) | 32850 (226) (2310) | 26020 (179) (1830) | 21050 (145) (1480) | | | 38470 (265) (2705) | 32280 (222) (2270) | 26170 (180) (1840) | 20620 (142) (1450) |

| Clamping force | USton (kN) (tf) |

123 (1100) (112) |

||||||||

| Clamping stroke | inch (mm) |

20.5 (520) |

||||||||

| Min. mold thickness | inch (mm) |

7.9 (200) |

||||||||

| Max. daylight opening | inch (mm) |

28.3 (720) |

||||||||

| Tie bar clearance (H×V) | inch (mm) |

18.1x18.1 (460x460) |

||||||||

| Die plate dimensions (H×V) | inch (mm) |

25.5x25.5 (647x647) |

||||||||

| Ejector stroke | inch (mm) |

3.3 (85) |

||||||||

| Item | Unit | 25A (std) | | | 36A | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Screw diameter | inch (mm) | AA 1.42 (36) | A 1.57 (40) | B 1.77 (45) | C 1.97 (50) | | | A 1.77 (45) | B 1.97 (50) | C 2.20 (56) | |

| Injection capacity | inch3 (cm3) (oz) | 9.9 (163) (5.5) | 12.3 (201) (6.7) | 15.5 (254) (8.5) | 19.2 (314) (10.5) | | | 17.5 (286) (9.6) | 21.5 (353) (11.8) | 27.0 (443) (14.8) | |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 36970 (255) (2600) | 31780 (219) (2235) | 25170 (173) (1770) | 20340 (140) (1430) | | | 30010 (207) (2110) | 24390 (168) (1715) | 19480 (134) (1370) | |

| Clamping force | USton (kN) (tf) |

154 (1370) (140) |

||||||||

| Clamping stroke | inch (mm) |

23.6 (600) |

||||||||

| Min. mold thickness | inch (mm) |

9.8 (250) |

||||||||

| Max. daylight opening | inch (mm) |

33.5 (850) |

||||||||

| Tie bar clearance (H×V) | inch (mm) |

20.1x20.1 (510x510) |

||||||||

| Die plate dimensions (H×V) | inch (mm) |

28.7x28.7 (730x730) |

||||||||

| Ejector stroke | inch (mm) |

3.5 (90) |

||||||||

| Item | Unit | 25A | | | 36A (std) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Screw diameter | inch (mm) | AA 1.42 (36) | A 1.57 (40) | B 1.77 (45) | C 1.97 (50) | | | A 1.77 (45) | B 1.97 (50) | C 2.20 (56) | |

| Injection capacity | inch3 (cm3) (oz) | 9.9 (163) (5.5) | 12.3 (201) (6.7) | 15.5 (254) (8.5) | 19.2 (314) (10.5) | | | 17.5 (286) (9.6) | 21.5 (353) (11.8) | 27.0 (443) (14.8) | |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 36970 (255) (2600) | 31780 (219) (2235) | 25170 (173) (1770) | 20340 (140) (1430) | | | 30010 (207) (2110) | 24390 (168) (1715) | 19480 (134) (1370) | |

| Clamping force | USton (kN) (tf) |

197 (1750) (179) |

||||||||

| Clamping stroke | inch (mm) |

27.6 (700) |

||||||||

| Min. mold thickness | inch (mm) |

9.8 (250) |

||||||||

| Max. daylight opening | inch (mm) |

37.4 (950) |

||||||||

| Tie bar clearance (H×V) | inch (mm) |

22.0x22.0 (560x560) |

||||||||

| Die plate dimensions (H×V) | inch (mm) |

31.5x31.5 (800x800) |

||||||||

| Ejector stroke | inch (mm) |

4.3 (110) |

||||||||

| Item | Unit | 50A (std) | | | 71A | ||||

|---|---|---|---|---|---|---|---|---|

| Screw diameter | inch (mm) | A 1.97 (50) | B 2.20 (56) | C 2.48 (63) | | | A 2.20 (56) | B 2.48 (63) | C 2.80 (71) |

| Injection capacity | inch3 (cm3) (oz) | 24.5 (402) (13.5) | 30.8 (505) (16.9) | 39.0 (639) (21.4) | | | 33.8 (554) (18.6) | 42.8 (701) (23.5) | 54.4 (891) (29.9) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 28730 (198) (2020) | 22900 (158) (1610) | 18200 (125) (1280) | | | 28440 (196) (2000) | 22470 (155) (1580) | 17710 (122) (1245) |

| Clamping force | USton (kN) (tf) |

237 (2110) (215) |

||||||

| Clamping stroke | inch (mm) |

29.9 (760) |

||||||

| Min. mold thickness | inch (mm) |

11.4 (290) |

||||||

| Max. daylight opening | inch (mm) |

41.3 (1050) |

||||||

| Tie bar clearance (H×V) | inch (mm) |

24.0x24.0 (610x610) |

||||||

| Die plate dimensions (H×V) | inch (mm) |

34.3x34.3 (870x870) |

||||||

| Ejector stroke | inch (mm) |

4.7 (120) |

||||||

| Item | Unit | 71A (std) | | | 100A | ||||

|---|---|---|---|---|---|---|---|---|

| Screw diameter | inch (mm) | A 2.20 (56) | B 2.48 (63) | C 2.80 (71) | | | A 2.48 (63) | B 2.80 (71) | C 3.15 (80) |

| Injection capacity | inch3 (cm3) (oz) | 33.8 (554) (18.6) | 42.8 (701) (23.5) | 54.4 (891) (29.9) | | | 48.5 (795) (26.6) | 61.6 (1010) (33.8) | 78.1 (1280) (42.9) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 28440 (196) (2000) | 22470 (155) (1580) | 17710 (122) (1245) | | | 29790 (205) (2095) | 23390 (161) (1645) | 18490 (127) (1300) |

| Clamping force | USton (kN) (tf) |

309 (2740) (280) |

||||||

| Clamping stroke | inch (mm) |

32.7 (830) |

||||||

| Min. mold thickness | inch (mm) |

12.6 (320) |

||||||

| Max. daylight opening | inch (mm) |

45.3 (1150) |

||||||

| Tie bar clearance (H×V) | inch (mm) |

26.0x26.0 (660x660) |

||||||

| Die plate dimensions (H×V) | inch (mm) |

37.6x37.6 (955x955) |

||||||

| Ejector stroke | inch (mm) |

5.1 (130) |

||||||

| Item | Unit | 100A (std) | | | 140A | ||||

|---|---|---|---|---|---|---|---|---|

| Screw diameter | inch (mm) | A 2.48 (63) | B 2.80 (71) | C 3.15 (80) | | | A 2.80 (71) | B 3.15 (80) | C 3.54 (90) |

| Injection capacity | inch3 (cm3) (oz) | 48.5 (795) (26.6) | 61.6 (1010) (33.8) | 78.1 (1280) (42.9) | | | 67.7 (1100) (37.2) | 86.0 (1410) (47.2) | 108.6 (1780) (59.6) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 29790 (205) (2095) | 23390 (161) (1645) | 18490 (127) (1300) | | | 28390 (195) (1990) | 22330 (154) (1570) | 17710 (122) (1245) |

| Clamping force | USton (kN) (tf) |

398 (3540) (361) |

||||||

| Clamping stroke | inch (mm) |

38.2 (970) |

||||||

| Min. mold thickness | inch (mm) |

13.8 (350) |

||||||

| Max. daylight opening | inch (mm) |

52.0 (1320) |

||||||

| Tie bar clearance (H×V) | inch (mm) |

28.9x28.9 (735x735) |

||||||

| Die plate dimensions (H×V) | inch (mm) |

41.5x41.5 (1055x1055) |

||||||

| Ejector stroke | inch (mm) |

5.9 (150) |

||||||

| Item | Unit | 160A (std) | ||

|---|---|---|---|---|

| Screw diameter | inch (mm) | A 2.80 (71) | B 3.15 (80) | C 3.54 (90) |

| Injection capacity | inch3 (cm3) (oz) | 77.5 (1270) (42.6) | 98.2 (1610) (54.0) | 123.9 (2030) (68.0) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 28390 (195) (1990) | 22330 (154) (1570) | 17710 (122) (1245) |

| Clamping force | USton (kN) (tf) |

501 (4460) (455) |

||

| Clamping stroke | inch (mm) |

40.4 (1025) |

||

| Min. mold thickness | inch (mm) |

14.8 (375) |

||

| Max. daylight opening | inch (mm) |

55.1 (1400) |

||

| Tie bar clearance (H×V) | inch (mm) |

32.3x32.3 (820x820) |

||

| Die plate dimensions (H×V) | inch (mm) |

46.9x46.9 (1190x1190) |

||

| Ejector stroke | inch (mm) |

6.3 (160) |

||

● Specifications apply to U.S. machines only.

● All specs and dimensions are subject to change without notice or may differ depending on export destinations and manufactured year.

● NISSEI is not responsible for any inaccuracies contained herein.

● Please consult our sales representative or NISSEI regional offices before designing a mold.

● Actual plasticizing capacity may vary, depending on the molding conditions and material used.