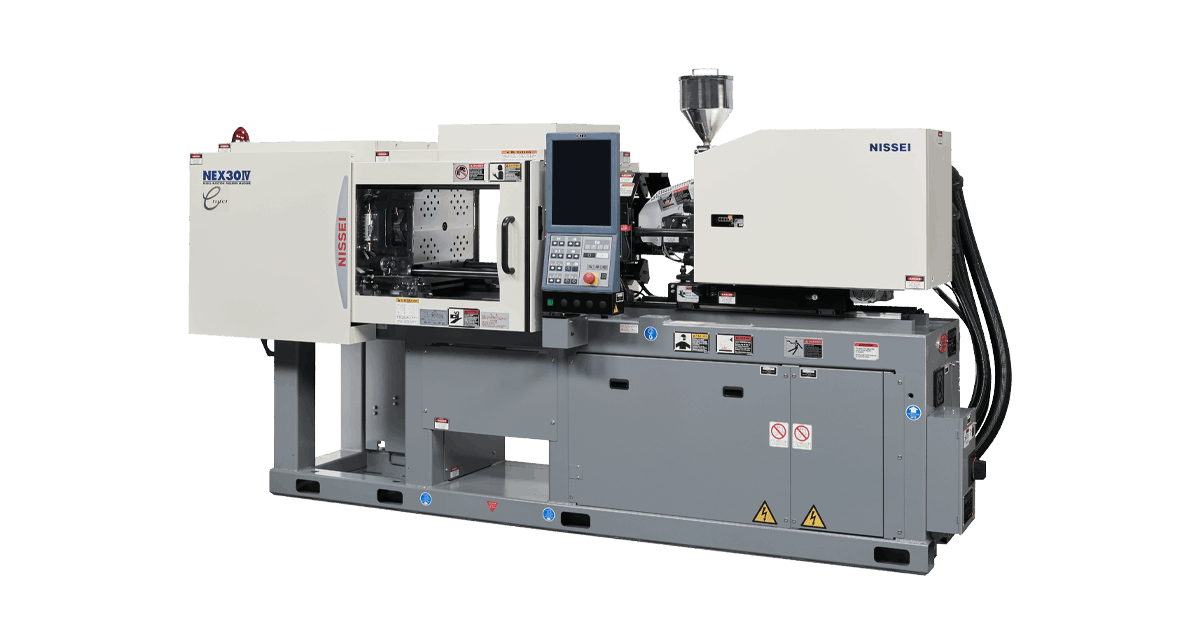

High-Precision Micro-Molding Machine

Offering Its Excellent Performance for the Medical Industry

There is a strong ongoing need for “micro-molding”

machines to produce micro precision molded parts.

Based on the NEX Series, which has a long track record of

being used in the medical equipment and electronic parts

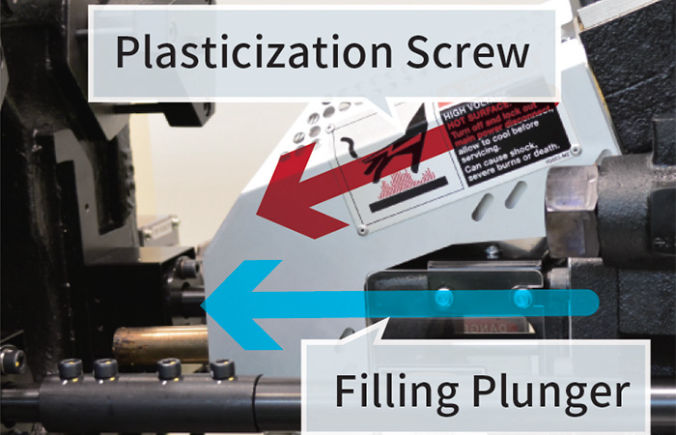

industries, NEX30 Ⅳ-1EN1 is equipped with the 2-stage

type high-precision injection unit, which consists of a

screw and plunger. It demonstrates supreme

performance in ultra-stable micro

molding under 1.0g per shot.