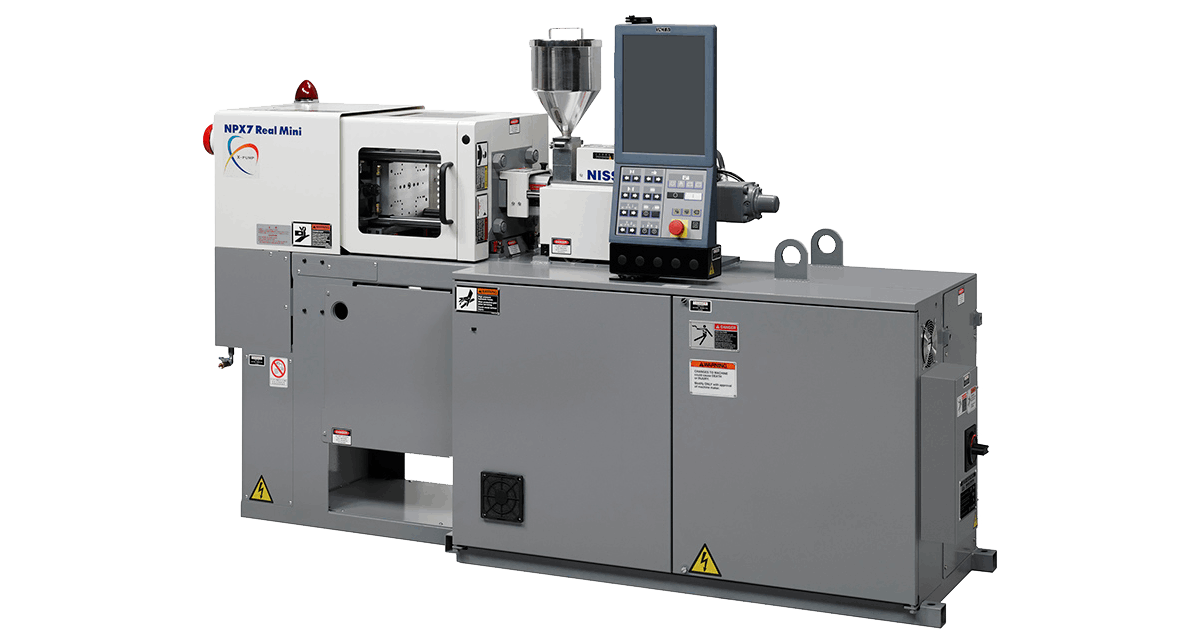

NPX7 Advance

COMPACT HYBRID TYPE INJECTION MOLDING MACHINE

7 ton (7.76 USton)

- Compact Hybrid

- Horizontal

- Direct Pressure Clamping

- TACT® Ⅳ Controller

- X-Pump System®

NPX7 Advance with NISSEI original innovative hybrid "X-Pump®" system possesses the advantages of both electric and hydraulic injection molding machines. It offers well-balanced performance with its high-rigidity direct-pressure clamping system, excellent injection performance, and supreme energy efficiency. It redefines the concept of hydraulic injection molding systems.

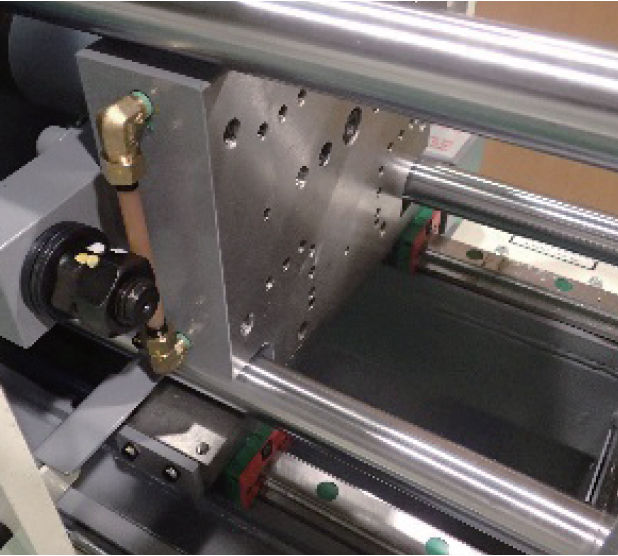

▶ Linear guide for movable platen slide base section

▶ Stable mold open/close movement and uniform mold pressure distribution

▶ Wide tie bar (170 x 155mm mold can be mounted)

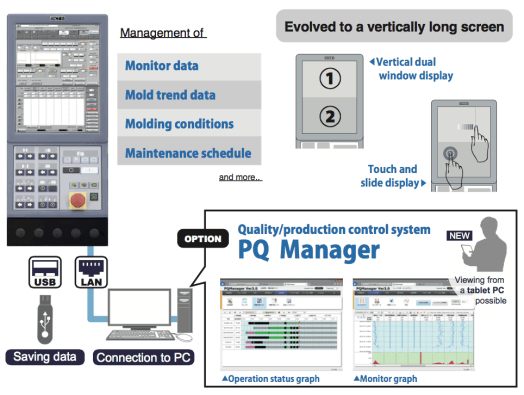

▶ Better operability and molding data management feature of the all-new TACT® Ⅳ Controller

| Item | Unit | |

|---|---|---|

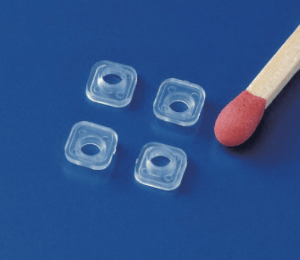

| Screw diameter | inch (mm) | 0.47 (12) |

| Injection capacity | inch3 (cm3) (oz) | 0.27 (4.5) (0.15) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 23070 (159) (1622) |

| Clamping force | USton (kN) (tf) |

7.76 (69) (7) |

| Clamping stroke | inch (mm) |

6.70 (170) |

| Min. mold thickness | inch (mm) |

4.33 (110) |

| Max. daylight opening | inch (mm) |

11.02 (280) |

| Tie bar clearance (H×V) | inch (mm) |

6.70x6.12 (170x155) |

| Die plate dimensions (H×V) | inch (mm) |

9.05x8.86 (230x225) |

| Ejector stroke | inch (mm) |

1.57 (40) |

● Specifications apply to U.S. machines only.

● All specs and dimensions are subject to change without notice or may differ depending on export destinations and manufactured year.

● NISSEI is not responsible for any inaccuracies contained herein.

● Please consult our sales representative or NISSEI regional offices before designing a mold.

● Actual plasticizing capacity may vary, depending on the molding conditions and material used.