PNX-III Series

SMALL HYBRID TYPE INJECTION MOLDING MACHINE

Clamping force: 41~65 ton (45~72 USton)

- Hybrid (Small-Size)

- Horizontal

- Direct Pressure Clamping

- TACT® Ⅳ Controller

- X-Pump System®

In spite of the rising popularity of electric injection molding machines in today's industry, NISSEI's original hybrid pump-equipped (X-Pump ) PNX-Ⅲ and FNX-Ⅲ series were created by combining the advantages of both hydraulic and electric type machines.

It offers outstanding well-balanced performance, enabling it to do a wide variety of molding from precision/thin-wall to thick-wall products. NISSEI hybrid type injection molding machines inherit the combination of hydraulic advantages (high-durability, low initial cost, low maintenance cost, and high-load injection capability), direct pressure clamping advantages (initial mold open linearity, contact pressure uniformity, and long stroke), and electric servomotor advantages (energy efficiency, high repeatability, high response, and low noise).

It redefines the concept of hydraulic injection molding systems.

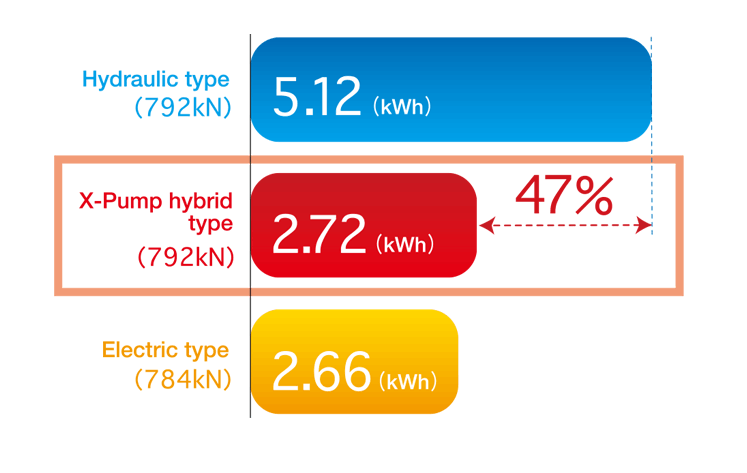

Comparison of power consumption

(Comparison with other NISSEI machines)

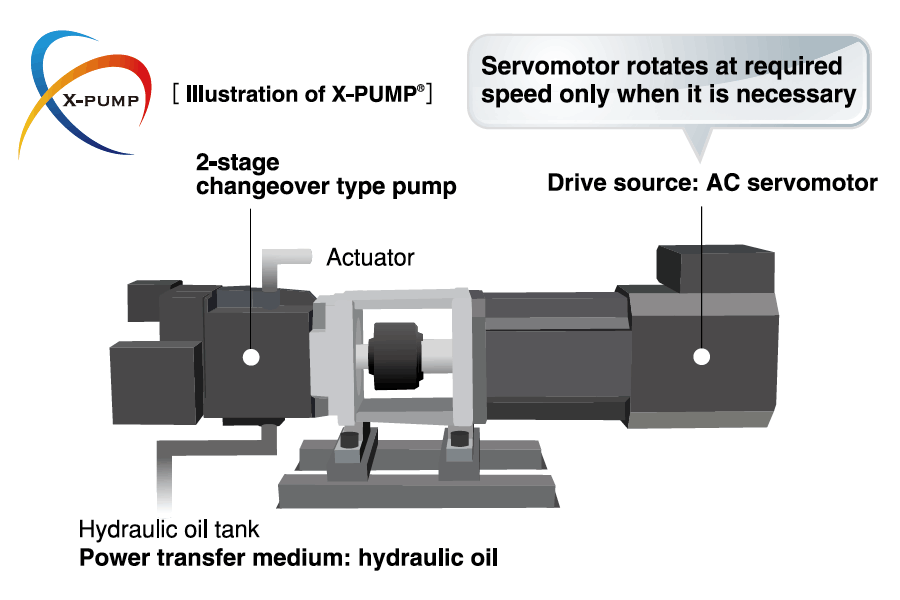

"Fusion of Hydraulic Control and Servomotor Drive Technologies"

The X-Pump System merges NISSEI’s time-tested hydraulic technologies with cutting-edge servomotor drive systems. Since the servomotor operates at required speed on demand, the X-Pump System delivers super energy efficient performance.

In addition, its exceptional injection repeatability and low velocity/pressure controllability make production of higher precision and quality products possible.

Larger screen, newly designed operation panel, and convenient & user-friendly premium software are equipped to improve workability & operability, and the quality & production management functions have been reinforced.

Sheet switch type is used for the operation panel, and 15-inch vertical LCD can arrange two windows vertically, materializing superior visibility and operability.

Molding condition settings to increase yield, which used to require a skilled technician, are automated and simplified. Its "Easy Setting" permits the reduction of defect rate.

In addition, new features, such as SET-UP screen and display of the descriptions of adjusters, allow saving of preparation time from mold installation to starting of mass production and materialization of easy & reliable operation.

| Item | Unit | 2A | | | 5A (std) | |||

|---|---|---|---|---|---|---|---|

| Screw diameter | inch (mm) | A 0.63 (16) | B 0.75 (19) | | | A 0.87 (22) | B 1.02 (26) | BB 1.10 (28) |

| Injection capacity | inch3 (cm3) (oz) | 0.79 (13) (0.44) | 1.1 (18) (0.6) | | | 2.1 (35) (1.2) | 3.0 (49) (1.6) | 3.5 (57) (1.9) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 39820 (274) (2800) | 30930 (213) (2175) | | | 40100 (276) (2820) | 30290 (209) (2130) | 26170 (180) (1840) |

| Clamping force | USton (kN) (tf) |

45 (405) (41) |

|||||

| Clamping stroke | inch (mm) |

11.8 (300) |

|||||

| Min. mold thickness | inch (mm) |

6.7 (170) |

|||||

| Max. daylight opening | inch (mm) |

18.5 (470) |

|||||

| Tie bar clearance (H×V) | inch (mm) |

12.2x12.2 (310x310) |

|||||

| Die plate dimensions (H×V) | inch (mm) |

17.7x17.7 (450x450) |

|||||

| Ejector stroke | inch (mm) |

2.4 (60) |

|||||

| Item | Unit | 5A (std) | ||

|---|---|---|---|---|

| Screw diameter | inch (mm) | A 0.87 (22) | B 1.02 (26) | BB 1.10 (28) |

| Injection capacity | inch3 (cm3) (oz) | 2.1 (35) (1.2) | 3.0 (49) (1.6) | 3.5 (57) (1.9) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 40100 (276) (2820) | 30290 (209) (2130) | 26170 (180) (1840) |

| Clamping force | USton (kN) (tf) |

72 (641) (65) |

||

| Clamping stroke | inch (mm) |

16.9 (430) |

||

| Min. mold thickness | inch (mm) |

6.7 (170) |

||

| Max. daylight opening | inch (mm) |

23.6 (600) |

||

| Tie bar clearance (H×V) | inch (mm) |

12.8x12.8 (325x325) |

||

| Die plate dimensions (H×V) | inch (mm) |

18.8x18.8 (478x478) |

||

| Ejector stroke | inch (mm) |

2.8 (70) |

||

● Specifications apply to U.S. machines only.

● All specs and dimensions are subject to change without notice or may differ depending on export destinations and manufactured year.

● NISSEI is not responsible for any inaccuracies contained herein.

● Please consult our sales representative or NISSEI regional offices before designing a mold.

● Actual plasticizing capacity may vary, depending on the molding conditions and material used.