TNX-RIII Series

VERTICAL HYBRID TYPE INJECTION MOLDING MACHINE

Clamping force: 53~150 ton (59~165 USton)

- Hybrid

- Vertical

- Turntable Type

- Center or Parting* Injections

- Direct Pressure Clamping

- TACT® Ⅳ Controller

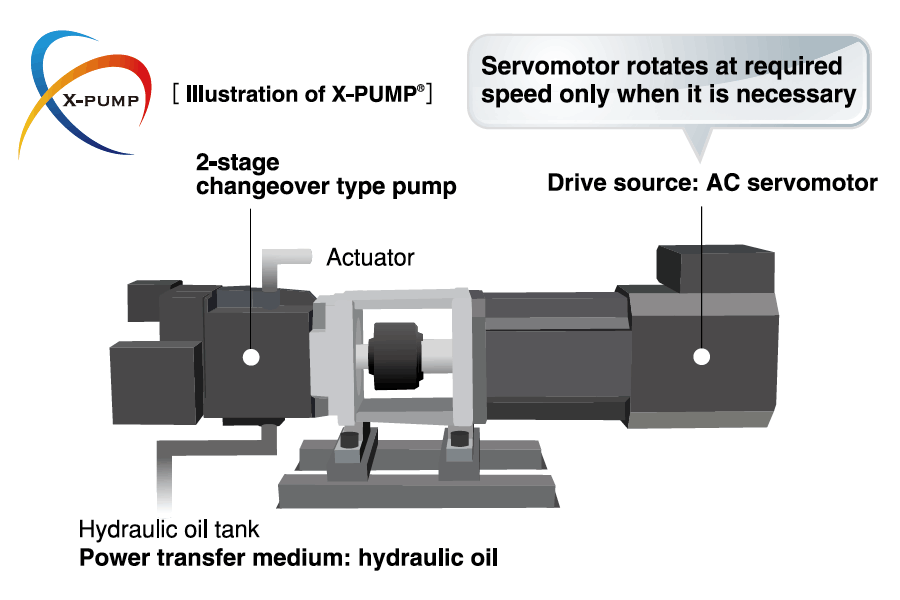

- X-Pump System®

* Parting types are made to order.