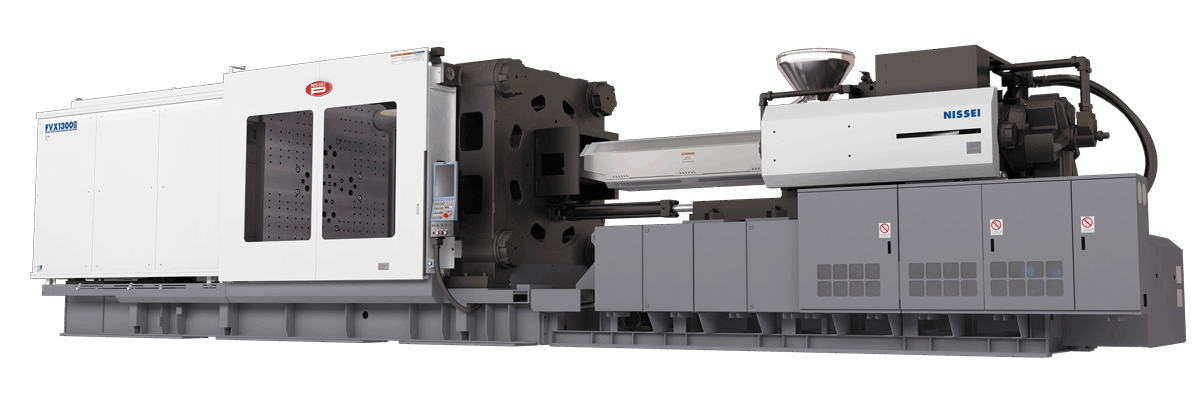

FVX-Ⅲ Series

LARGE HYBRID TYPE INJECTION MOLDING MACHINE

561~1306 ton (618~1439 USton)

- Hybrid (Large-Size)

- Horizontal

- Direct Pressure Clamping

- TACT® Ⅳ Controller

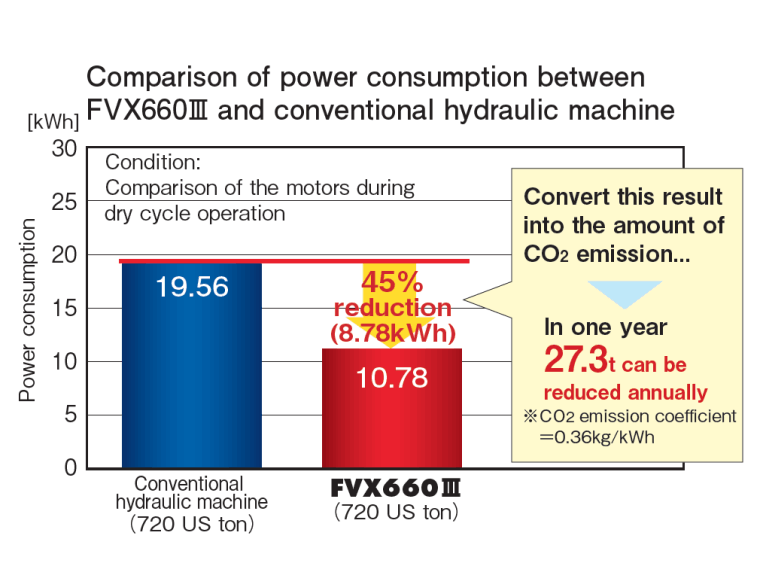

- X-Pump System®

FVX-Ⅲ Series inherits easy-operability and straight-hydraulic mold clamping advantages of hydraulic injection molding machines while achieving significant energy-savings.

FVX-Ⅲ Series with NISSEI original innovative hybrid "X-Pump®" system offers well-balanced performance with its high-rigidity direct-pressure clamping system, excellent injection performance, long service life, easy maintenance, and electric type level of energy efficiency.

It redefines the concept of hydraulic injection molding systems.

Larger screen, newly designed operation panel, and convenient & user-friendly premium software are equipped to improve workability & operability, and the quality & production management functions have been reinforced.

Sheet switch type is used for the operation panel, and 15-inch vertical LCD can arrange two windows vertically, materializing superior visibility and operability.

Molding condition settings to increase yield, which used to require a skilled technician, are automated and simplified. Its "Easy Setting" permits the reduction of defect rate.

In addition, new features, such as SET-UP screen and display of the descriptions of adjusters, allow saving of preparation time from mold installation to starting of mass production and materialization of easy & reliable operation.

| Item | Unit | 210L | | | 310L | ||

|---|---|---|---|---|---|---|

| Screw diameter | inch (mm) | 3.1 (80) | 3.5 (90) | | | 3.5 (90) | 3.9 (100) |

| Injection capacity | inch3 (cm3) (oz) | 219 (2110) (70.7) | 163 (2670) (89.5) | | | 194 (3180) (107) | 240 (3930) (132) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 27020 (186) (1900) | 21330 (147) (1500) | | | 26560 (183) (1870) | 21480 (148) (1510) |

| Clamping force | USton (kN) (tf) |

618 (5500) (561) |

||||

| Clamping stroke | inch (mm) |

35.4 (900) |

||||

| Mold thickness (min.-max.) | inch (mm) |

15.7~35.4 (400~900) |

||||

| Max. daylight opening | inch (mm) |

71.3 (1810) |

||||

| Tie bar clearance (H×V) | inch (mm) |

38.2x38.2 (970x970) |

||||

| Die plate dimensions (H×V) | inch (mm) |

53.5x53.5 (1360x1360) |

||||

| Ejector stroke | inch (mm) |

7.1 (180) |

||||

| Item | Unit | 310L | | | 400L | ||

|---|---|---|---|---|---|---|

| Screw diameter | inch (mm) | 3.5 (90) | 3.9 (100) | | | 3.9 (100) | 4.4 (112) |

| Injection capacity | inch3 (cm3) (oz) | 194 (3180) (107) | 240 (3930) (132) | | | 244 (4000) (134) | 306 (5020) (168) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 26560 (183) (1870) | 21480 (148) (1510) | | | 24230 (167) (1710) | 19340 (133) (1360) |

| Clamping force | USton (kN) (tf) |

720 (6390) (653) |

||||

| Clamping stroke | inch (mm) |

37.4 (950) |

||||

| Mold thickness (min.-max.) | inch (mm) |

17.7~37.4 (450~950) |

||||

| Max. daylight opening | inch (mm) |

75.2 (1910) |

||||

| Tie bar clearance (H×V) | inch (mm) |

43.3x43.3 (1100x1100) |

||||

| Die plate dimensions (H×V) | inch (mm) |

60.6x60.6 (1540x1540) |

||||

| Ejector stroke | inch (mm) |

7.9 (200) |

||||

| Item | Unit | 400L | | | 600L | ||

|---|---|---|---|---|---|---|

| Screw diameter | inch (mm) | 3.9 (100) | 4.4 (112) | | | 4.4 (112) | 4.9 (125) |

| Injection capacity | inch3 (cm3) (oz) | 244 (4000) (134) | 306 (5020) (168) | | | 367 (6010) (201) | 456 (7480) (251) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 24320 (167) (1710) | 19340 (133) (1360) | | | 24890 (171) (1750) | 20050 (138) (1410) |

| Clamping force | USton (kN) (tf) |

946 (8410) (858) |

||||

| Clamping stroke | inch (mm) |

46.3 (1175) |

||||

| Mold thickness (min.-max.) | inch (mm) |

19.7~42.3 (500~1075) |

||||

| Max. daylight opening | inch (mm) |

89.0 (2260) |

||||

| Tie bar clearance (H×V) | inch (mm) |

52.4x52.4 (1330x1330) |

||||

| Die plate dimensions (H×V) | inch (mm) |

70.9x70.9 (1800x1800) |

||||

| Ejector stroke | inch (mm) |

7.9 (200) |

||||

| Item | Unit | 600L | |

|---|---|---|---|

| Screw diameter | inch (mm) | 4.4 (112) | 4.9 (125) |

| Injection capacity | inch3 (cm3) (oz) | 367 (6010) (201) | 456 (7480) (251) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 24890 (171) (1750) | 20050 (138) (1410) |

| Clamping force | USton (kN) (tf) |

1207 (10730) (1095) |

|

| Clamping stroke | inch (mm) |

49.2 (1250) |

|

| Mold thickness (min.-max.) | inch (mm) |

23.6~45.3 (600~1150) |

|

| Max. daylight opening | inch (mm) |

94.9 (2410) |

|

| Tie bar clearance (H×V) | inch (mm) |

55.1x55.1 (1400x1400) |

|

| Die plate dimensions (H×V) | inch (mm) |

78.0x78.0 (1980x1980) |

|

| Ejector stroke | inch (mm) |

7.9 (200) |

|

| Item | Unit | 700L | | | 1100L* | |||

|---|---|---|---|---|---|---|---|

| Screw diameter | inch (mm) | 4.7 (112) | 5.3 (135) | | | 4.9 (125) | 5.5 (140) | 5.9 (150) |

| Injection capacity | inch3 (cm3) (oz) | 428 (7010) (235) | 541 (8870) (297) | | | 535 (8774) (294) | 672 (11006) (369) | 771 (12635) (423) |

| Max. injection pressure | psi (MPa) (kgf/cm2) | 24460 (168) (1720) | 19340 (133) (1360) | | | 29150 (201) (2050) | 23180 (160) (1630) | 20340 (140) (1430) |

| Clamping force | USton (kN) (tf) |

1439 (12800) (1306) |

|||||

| Clamping stroke | inch (mm) |

51.2 (1300) |

|||||

| Mold thickness (min.-max.) | inch (mm) |

27.6~49.2 (700~1250) |

|||||

| Max. daylight opening | inch (mm) |

100.8 (2560) |

|||||

| Tie bar clearance (H×V) | inch (mm) |

57.1x57.1 (1450x1450) |

|||||

| Die plate dimensions (H×V) | inch (mm) |

79.5x79.5 (2020x2020) |

|||||

| Ejector stroke | inch (mm) |

11.0 (280) |

|||||

● Specifications apply to U.S. machines only.

● All specs and dimensions are subject to change without notice or may differ depending on export destinations and manufactured year.

● NISSEI is not responsible for any inaccuracies contained herein.

● Please consult our sales representative or NISSEI regional offices before designing a mold.

● Actual plasticizing capacity may vary, depending on the molding conditions and material used.

* These are estimated values for FVX1300Ⅲ-1100L. Please contact us for more details.