NISSEI PREVENTIVE MAINTENANCE PLAN

We offer preventive maintenance plans in addition to our quick-responding repair services.

We strive to provide excellent service and quality care with a customer-centric approach.

We offer preventive maintenance plans in addition to our quick-responding repair services.

We strive to provide excellent service and quality care with a customer-centric approach.

We provide services to keep your machines running efficiently and minimize downtime with the identification of leaks, abnormal heat and noises, electrical problems, and other damages.

Machines that maintain their factory specifications

are vital to steady production scheduling, less processing changes, and faster start ups.

"Reducing performance gap between the same machine types"

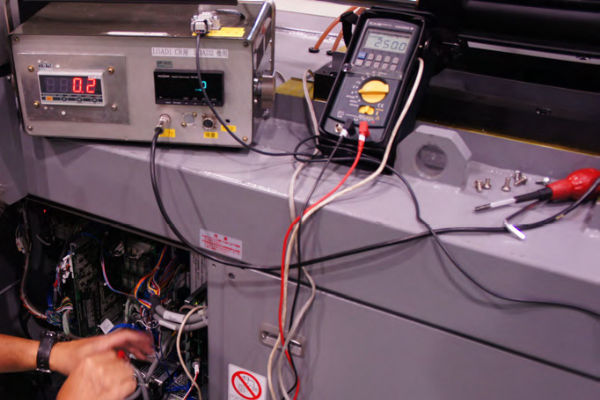

For the performance restoration plan, an experienced staff uses a special instrument to measure each machine' s performance in numerical values.

The results will be compared with the reference values. If something deviates from its standard value, it will be adjusted. This can reduce the performance gap between the same machine types. After restoration, an inspection report for each machine will be issued.

- Check injection load cell resistance

- Check Injection stroke time

- Check and adjust tie bar balance

- Calibrate nozzle and barrel temperatures

- Check and adjust pump flow linearity

- Check and adjust pump pressure linearity

- Calibrate nozzle and barrel temperatures

"Cleaning, inspection, adjustment, greasing, and prevention of sudden failure"

For the maintenance & inspection plan, preventive maintenance, such as inspecting electrical components and safety devices, will be performed

according to a NISSEI checklist; parts that need to be replaced will be identified in order to minimize the risk of unexpected failures.

Some components inside of the machine are difficult to see, and inspecting certain components requires special instruments and knowledge. Small issues can go unnoticed when normally operating a machine. NISSEI recommends a scheduled maintenance & inspection plan in order to detect minor issues before turning into major problems. After maintenance and inspection, a checklist with recommended replacement parts and its quotation for labor will be sent to the clients.

- Check electrical components

- Check looseness and rattling of mechanical components

- Check safety devices

- Inspect toothed belt, check tension, and adjust

- Feed grease to support bearing

- Clean micro separator

- Check and clean suction filter

- Check hydraulic oil condition

- Check hydraulic oil leaks

| Plans | 1st year | 2nd year | 3rd year | 4th year | 5th year | 6th year | 7th year | 8th year | 9th year | 10th year |

|---|---|---|---|---|---|---|---|---|---|---|

| Performance restoration | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Maintenance & inspection | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Common options | ① | ① | ① ④ | ① ⑤ ⑥ | ① ⑦ | ① ④ ⑧ | ① | ① ⑤ ⑥ | ① ④ | ① ⑦ |

*Please contact NISSEI if you need a maintenance plan for the machines that have been used for more than 10 years.

*For OP 1~8, please refer to the option list below.

| No. | Option type | Electric | Hydraulic | Hybrid |

|---|---|---|---|---|

| ① | Remove and clean grease | ○ | ||

| ② | Calibrate injection load cell (Japan only) | Not avail | Not avail | Not avail |

| ③ | Clean oil leak and reservoir | ○ | ○ | |

| ④ | Replace cooling fan | ○ | ○ | ○ |

| ⑤ | Replace magnetic contactor | ○ | ○ | ○ |

| ⑥ | Replace toothed belt | ○ | ||

| ⑦ | Replace lithium battery | ○ | ○ | ○ |

| ⑧ | Replace rubber hose | ○ | ○ | |

| ⑨ | Built your own plan | ○ | ○ | ○ |